Embrace the Digital Enterprise with Smart Factory Sensors

Embrace the Digital Enterprise with Smart Factory Sensors (1min)

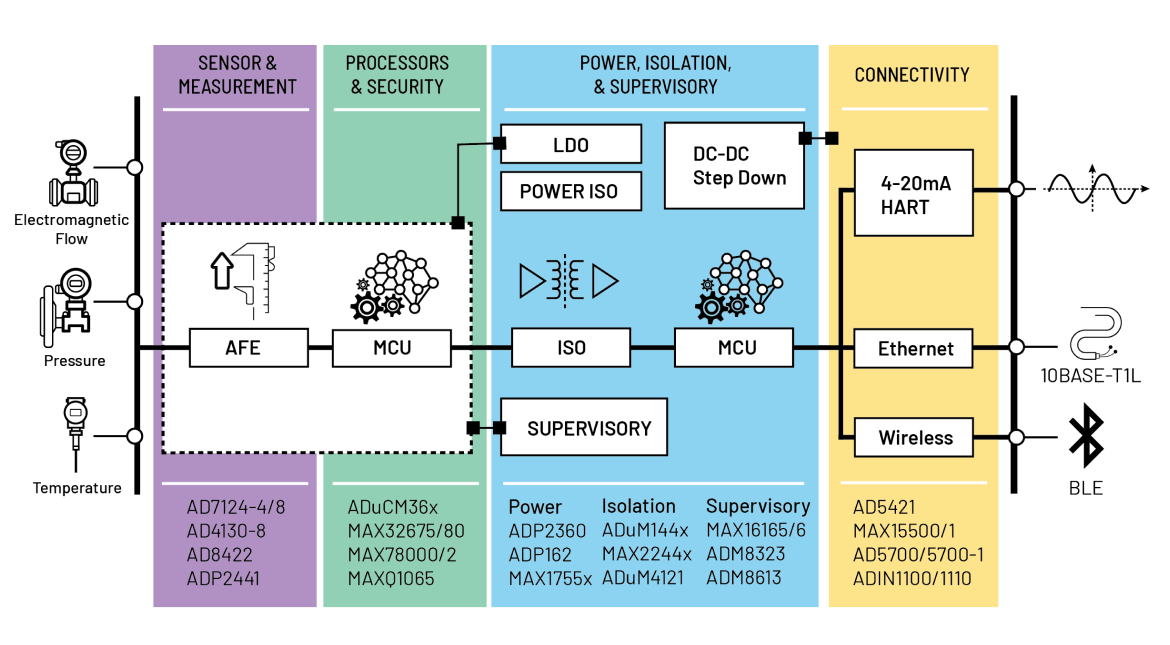

Smart factories need intelligent sensors and actuators that enhance decision-making actions, enabling more flexible and optimized manufacturing processes. IO-Link® technology transforms traditional sensors into intelligent sensors, facilitating real-time configurable factory production lines. IO-Link is a new technology introduced by Analog Devices in the L-Maxim series, representing that our customers may not yet fully understand the benefits Analog Devices can bring in this field. By using newly created content, we aim to outline the key values that Analog Devices can offer to our customers in the following capabilities:

Increase Productivity

Avoid Unplanned Downtime

Improve Process & Product Quality

Actionable Insights

Sustainable Manufacturing

Reduce Energy Consumption

Market & Growth Areas

According to the IO-Link Alliance report, the IO-Link node market has grown from 20 million in 2012 to 27.3 million units in 2022, and continues to grow. Analog Devices' perspective in this area: Europe, the Middle East, and Africa are adopting IO-Link at the fastest rate, and currently account for the majority of the business. As the implementation of electric vehicle battery factories progresses, China is rapidly promoting IO-Link (including master stations and devices). The United States is adopting IO-Link at a slower pace, but as the region is moving towards in-house subcontracting, it is emerging as a potential opportunity market, with IO-Link being an attractive solution.

- Overcoming the Power vs. Space Conundrum in Smart Factory Sensors

- How to Design Fieldbus-Agnostic Smart Factory Sensors

- Sensors Step Back, Actuators Enter the Smart Factory Stage

- How IO-Link Brings 'Real Intelligence' to Smart Factories

- Three Reasons Why IO-Link is Changing Decision-Making in Smart Factories

Featured Products

Due to the high volume of inquiries, our response times are slower than usual. We’re working hard to get to your message ASAP. Thanks for your patience!

Provide WTMEC FAE AI Assistant service, and the robot will respond to your basic questions

Company Info:

14F., No. 738, Zhongzheng Rd., Zhonghe Dist., New Taipei City 235603, Taiwan (R.O.C.)

TEL: +886-2-8226-9088

FAX: +886-2-8226-9099